Login

Contact

Description

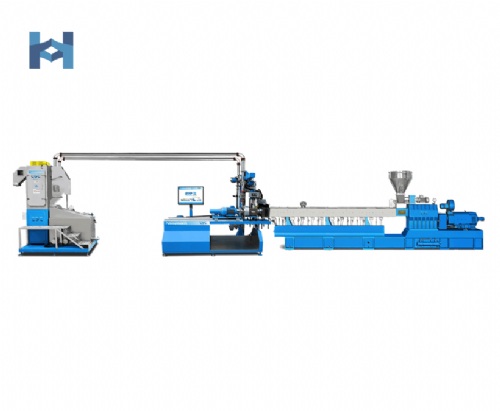

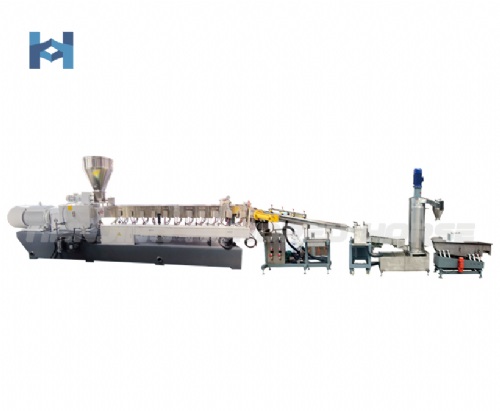

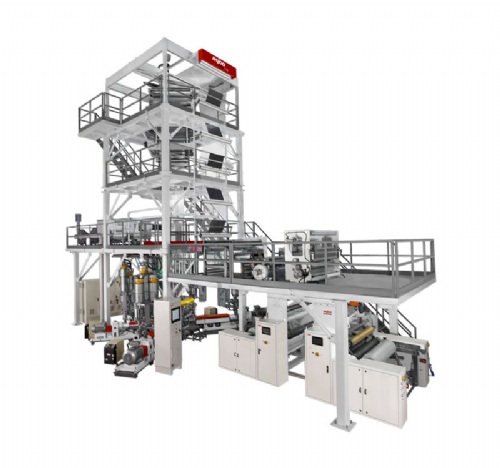

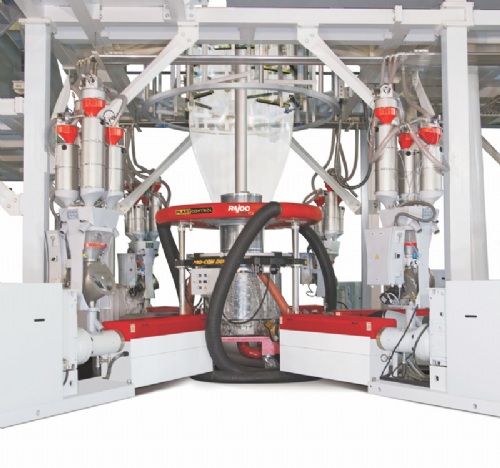

Granuwel’s three-screw extusion are specifically designed for better dispersion and greater yields. The free volume of the screw is increased by 40%. Carbon black, CaCO3 and other powders are easier to feed, and the screws mesh with each other, providing a faster surface renewal rate, so the mixing effect is significantly better than that of Twin screw extruder.

The structure of the three-screw extusion machine is characterized by three screws arranged in a straight line and rotating in the same direction, the three-screw extusion machine than the traditional Twin screw extruder more than a high shear zone, so as to achieve the same specifications of the Twin screw extruder plasticizing mixing performance doubled, so the production capacity of the three-screw double the double screw.https://granuwelextruder.com/gse-series-triple-screw-extruder/

The structure of the three-screw extusion machine is characterized by three screws arranged in a straight line and rotating in the same direction, the three-screw extusion machine than the traditional Twin screw extruder more than a high shear zone, so as to achieve the same specifications of the Twin screw extruder plasticizing mixing performance doubled, so the production capacity of the three-screw double the double screw.https://granuwelextruder.com/gse-series-triple-screw-extruder/

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry