Login

Contact

Description

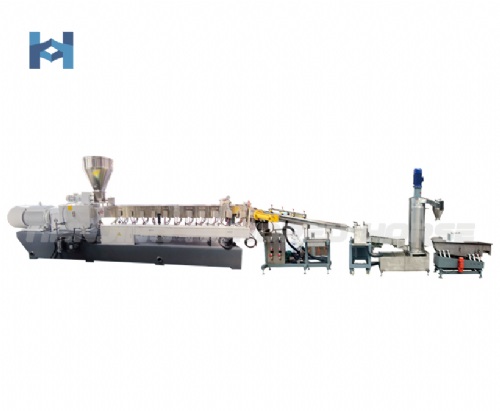

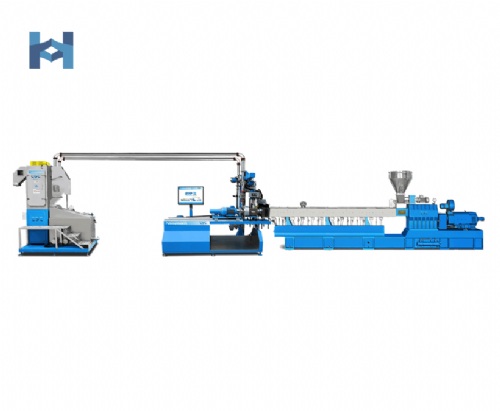

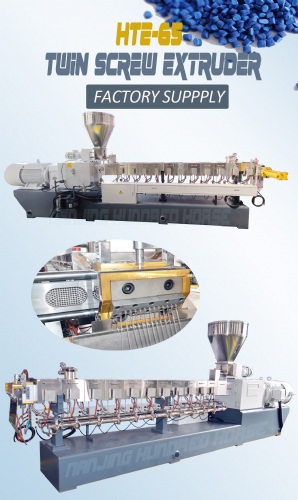

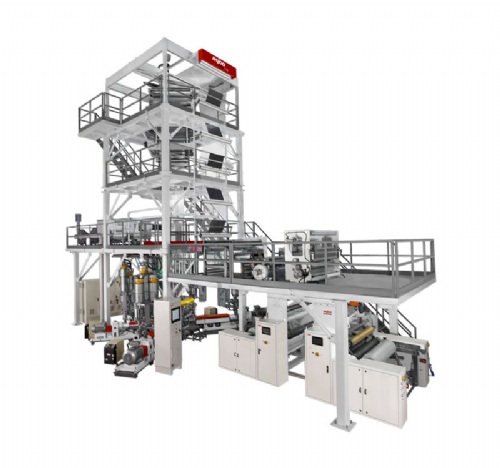

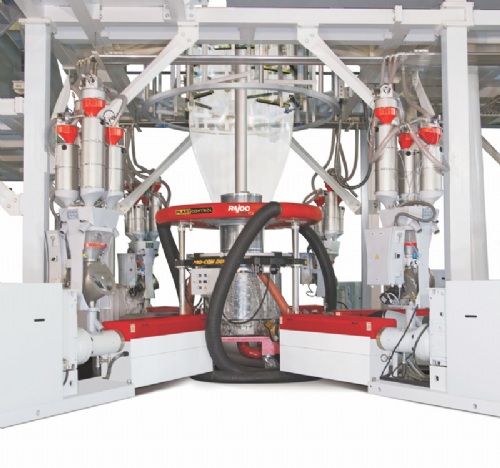

Twin screw extruder for plastic compounding and pelletizing

Model#: HTE75

Screw diameter: 71mm

Output:300-500kg/hr

Typical applications include: color masterbatches, black/white masterbatches, filler masterbatches, additive functional masterbatches, engineering plastics, elastomers, biodegradable materials and so on.

Model#: HTE75

Screw diameter: 71mm

Output:300-500kg/hr

Typical applications include: color masterbatches, black/white masterbatches, filler masterbatches, additive functional masterbatches, engineering plastics, elastomers, biodegradable materials and so on.

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry