Login

Contact

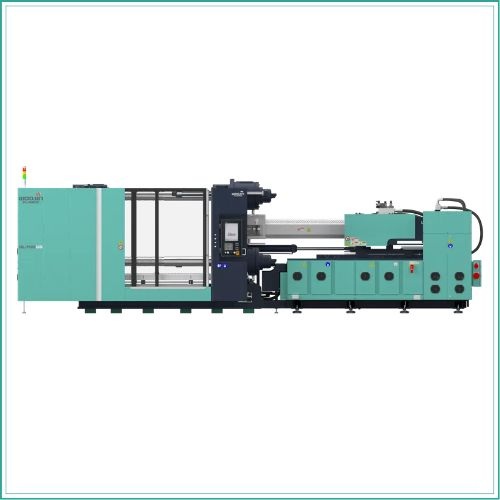

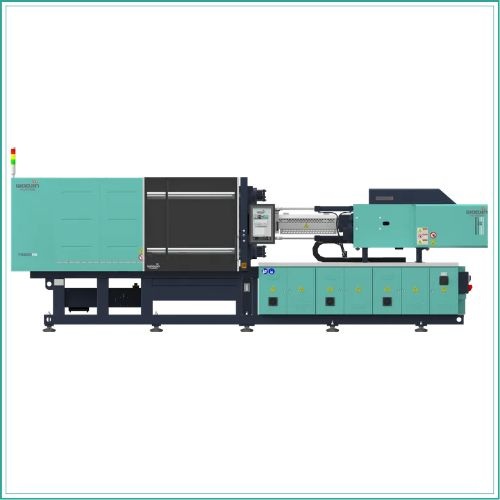

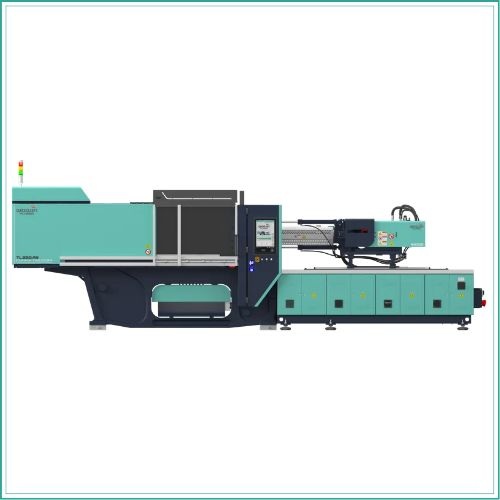

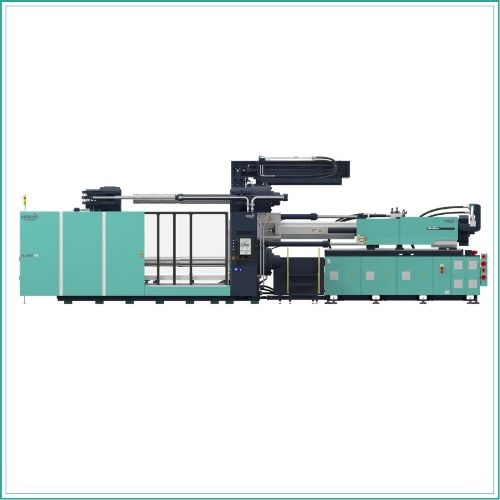

Description

Core Advantages: More, Fast, Good, Save

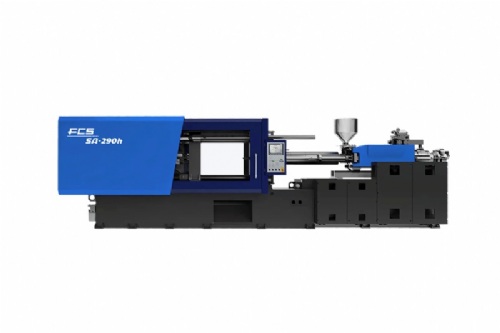

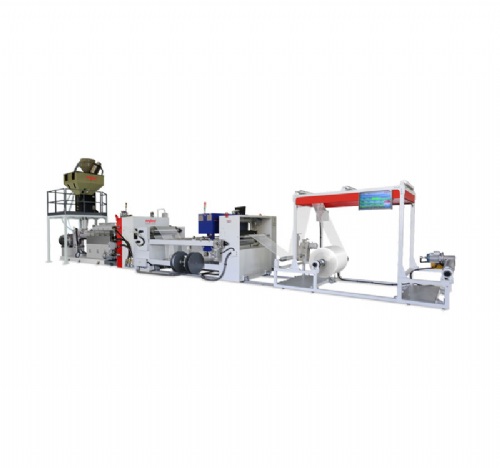

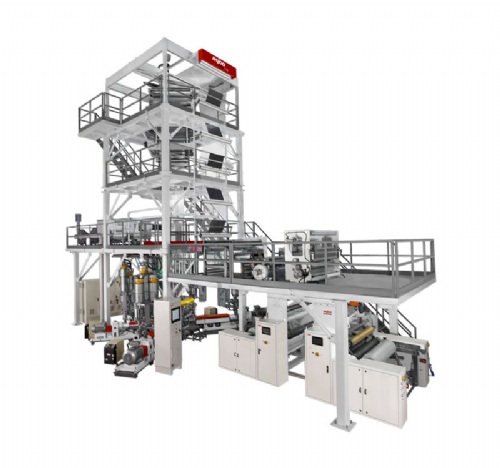

The EVOlution hybrid injection molding machine is promoted based on four key competitive advantages:

More: It achieves a higher output rate under equivalent conditions.

Fast: The machine offers an injection speed that is over 50% faster and reduces the molding cycle by 20-30%.

Good: It provides simpler adjustment, 30% higher precision, less flash on products, and a higher qualification rate (fewer defects).

Save: It excels in energy savings, reducing electricity costs by up to 30%. One source claims it can "make you an extra machine in two years," highlighting its rapid return on investment.

Technical Features and System Integration

Smart Motion Control System: The EVOlution integrates mechanical, electrical, hydraulic, and control systems. When combined with BOLE's core algorithm, this system enhances overall machine performance, improving both precision and speed by 30% and achieving significant energy savings.

Center Lock Mold Structure (for EKW/EKS models): While not exclusively for the EVOlution, this structure is used in other Bole series like the EKW wide-plate and EKS precision machines. It offers benefits such as faster opening/clamping speed (30% faster than traditional hydraulic machines), higher utilization of the clamping force, and the ability to save 1-3% on material for many molds.

Summary

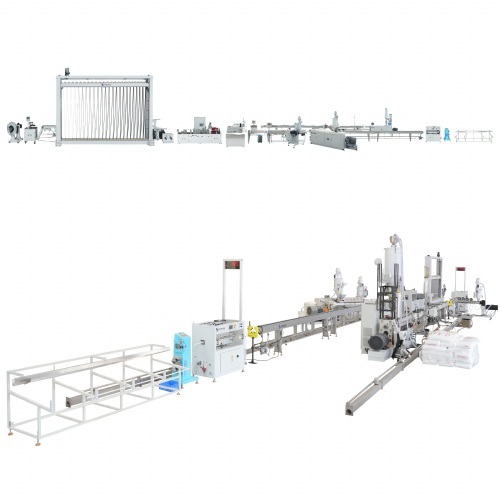

In short, the BOLE EVOlution hybrid injection molding machine is defined by its **high efficiency, precision, significant energy savings, and smart control system**. Its core value proposition is delivering higher output with better quality at a lower operational cost, encapsulated in the "More, Fast, Good, Save" philosophy. The company further reinforces its technical expertise with specialized solutions for lightweight composite and metal parts.

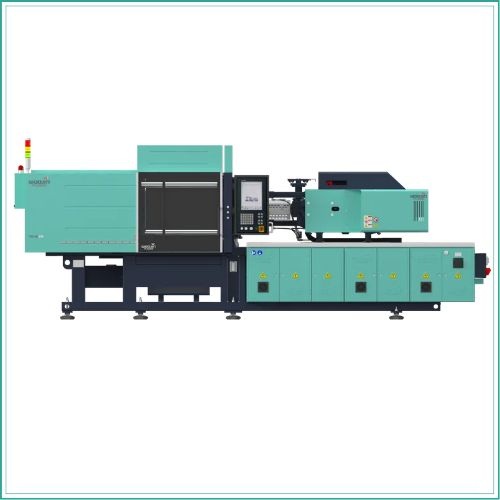

The EVOlution hybrid injection molding machine is promoted based on four key competitive advantages:

More: It achieves a higher output rate under equivalent conditions.

Fast: The machine offers an injection speed that is over 50% faster and reduces the molding cycle by 20-30%.

Good: It provides simpler adjustment, 30% higher precision, less flash on products, and a higher qualification rate (fewer defects).

Save: It excels in energy savings, reducing electricity costs by up to 30%. One source claims it can "make you an extra machine in two years," highlighting its rapid return on investment.

Technical Features and System Integration

Smart Motion Control System: The EVOlution integrates mechanical, electrical, hydraulic, and control systems. When combined with BOLE's core algorithm, this system enhances overall machine performance, improving both precision and speed by 30% and achieving significant energy savings.

Center Lock Mold Structure (for EKW/EKS models): While not exclusively for the EVOlution, this structure is used in other Bole series like the EKW wide-plate and EKS precision machines. It offers benefits such as faster opening/clamping speed (30% faster than traditional hydraulic machines), higher utilization of the clamping force, and the ability to save 1-3% on material for many molds.

Summary

In short, the BOLE EVOlution hybrid injection molding machine is defined by its **high efficiency, precision, significant energy savings, and smart control system**. Its core value proposition is delivering higher output with better quality at a lower operational cost, encapsulated in the "More, Fast, Good, Save" philosophy. The company further reinforces its technical expertise with specialized solutions for lightweight composite and metal parts.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry