Login

Contact

Description

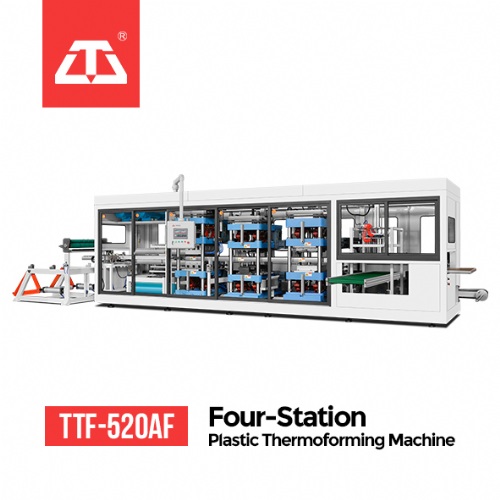

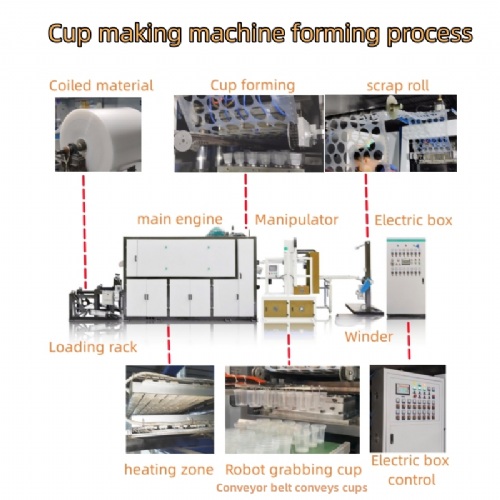

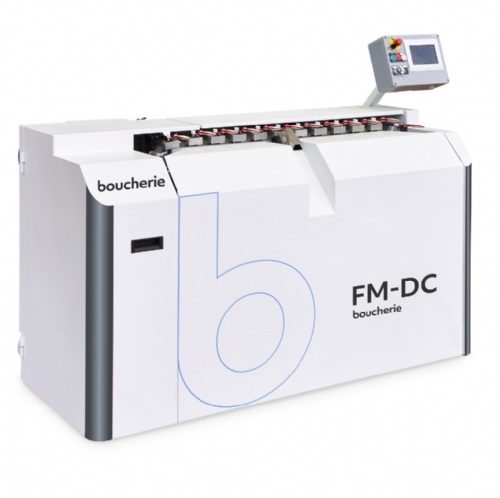

Plastic cup thermoforming machine is our lasted developed product, Sheet feeding and stretching part are driven by servo motor. Machine produces disposable products, such as plastic cup, bowl, lid, and box through the workflow of sheet feeding, sheet heating, forming, cutting and blowing, widely used and suitable for most of the customer requested. PLC for program, manual interface for operation, stable, low noise, and high efficiency.Industrial manual interface and PLC of SIEMENS (Germany) make the high degree automation, accurate control and convenient operation. The document storage function simplifies the operational processes.Working stations is driven by stable four guiding-pillars (GCr15 steel, outside is hard chrome plated) structure. Wear resistant, and extend equipment life.Stretching servomotor of YASKAWA (Japan) controls the speed of the upper and lower die, this can maintain the uniform strength to ensure that the bottom thickness of each cup is uniformly.

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry