Login

Contact

Description

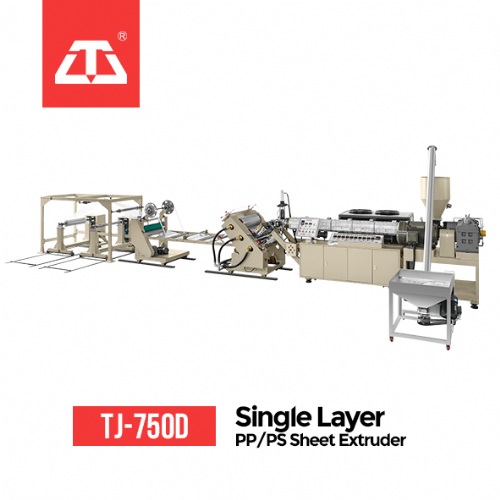

The sheet extruder is composed of extrusion, calendaring, traction and rolling. The main parts are abrasion resistant, resistant to corrosion, high-temperature resistant by high quality specially-treated. Low resistance force in die head extruding channel makes sheet thickness evenly, the internal spiral tank in three rollers ensures an effective cooling and it is easy to change and install net changer with the hydraulic pressure unit, no need to stop machine. The machine extrudes PP/PS granule to PP/PS sheet with single color, which is used for producing plastic products by plastic thermoforming machines, like cups, food container, trays, dishes, bowls, lids, etc.after nitrogen treatment with optimum hardness, strong corrosion resistance and long service lifetime.T-die Design: like cloth-hanger, enable the melting material be flowed evenly from the outlet.Roller layout way: by L type Inclined type , each roller arranged side by side.Double working station is easy to receive sheet.

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry