Login

Contact

Description

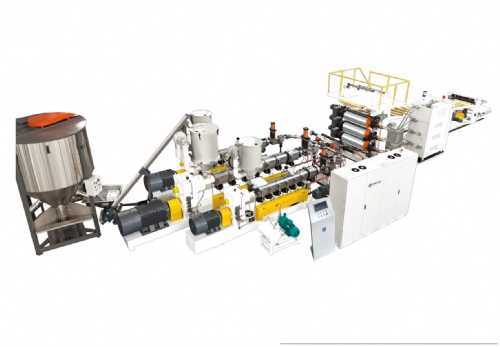

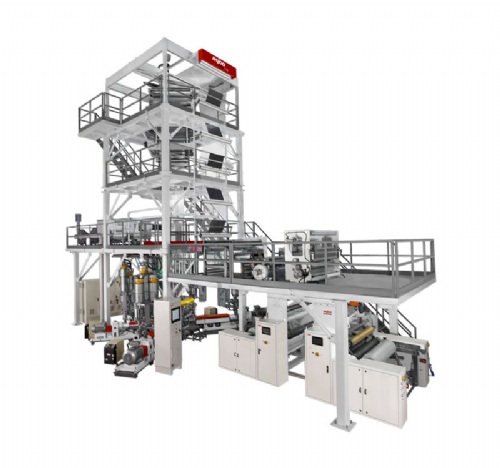

High degree of automation and continuity: From raw material input to finished product packaging, the entire process can achieve automated continuous production with minimal human intervention, high production efficiency, and stable product quality.

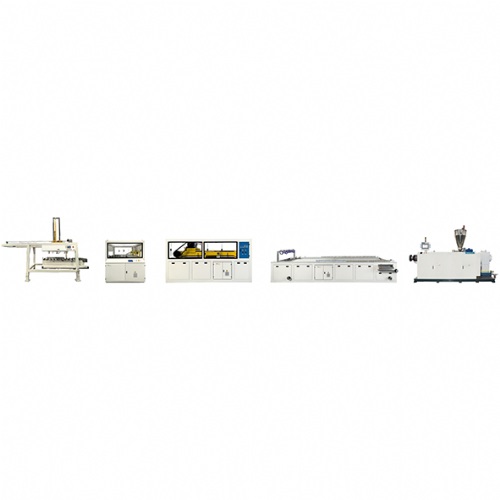

Precise Temperature Control: Each section of the extruder, die head, and cooling water tank features segmented, independent PID precise temperature control, crucial for ensuring plasticizing quality and dimensional accuracy.

Speed ??Synchronization: The speeds of each unit, including extrusion, haul-off, and winding, are centrally controlled by a PLC to maintain strict synchronization and prevent stretching or accumulation.

Thickness and Dimensional Control: Optional online thickness and width gauge and precise die and haul-off control ensure extremely small tolerances in the thickness and width of the edge banding.

The high performance of our production line directly determines the final high quality of the edge banding.

Precise Temperature Control: Each section of the extruder, die head, and cooling water tank features segmented, independent PID precise temperature control, crucial for ensuring plasticizing quality and dimensional accuracy.

Speed ??Synchronization: The speeds of each unit, including extrusion, haul-off, and winding, are centrally controlled by a PLC to maintain strict synchronization and prevent stretching or accumulation.

Thickness and Dimensional Control: Optional online thickness and width gauge and precise die and haul-off control ensure extremely small tolerances in the thickness and width of the edge banding.

The high performance of our production line directly determines the final high quality of the edge banding.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry