Login

Contact

Description

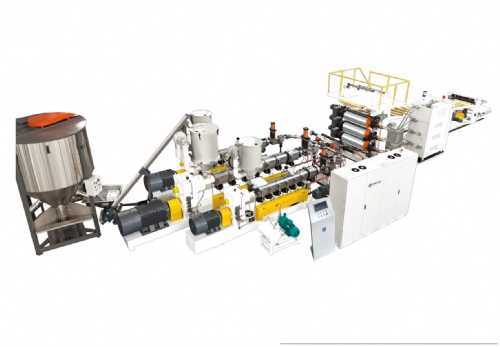

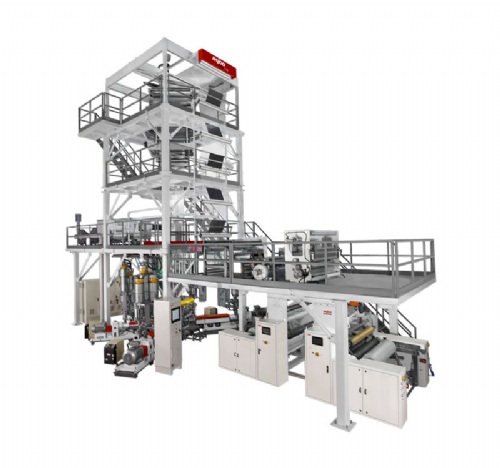

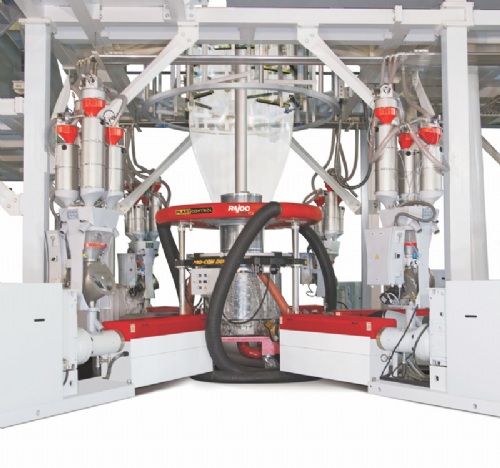

The PS foam extrusion unit uses PS (polystyrene) as raw material and employs a two-stage series screw for foaming sheet production. During the extrusion process, the PS raw material is injected with a foaming agent under high pressure. After mixing by the barrel and screw, the material is foamed, then passed through the extrusion die, cooled, shaped, drawn, and collected into finished sheets. After a 4-7 day setting period, the sheets are vacuum-formed and can be made into various packaging containers, such as disposable lunch boxes, instant noodle bowls, plates, and trays. These are widely used in food, fruit, advertising, automotive interior insulation, industrial products, and building products.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry