Login

Contact

Description

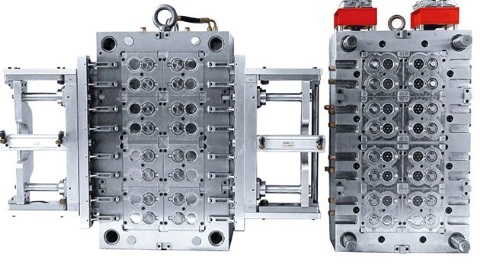

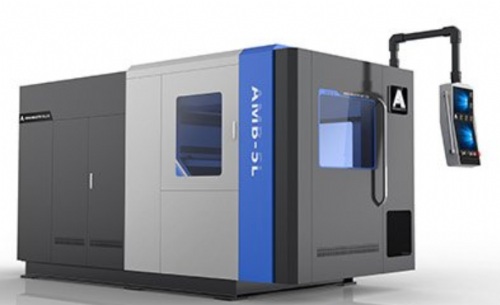

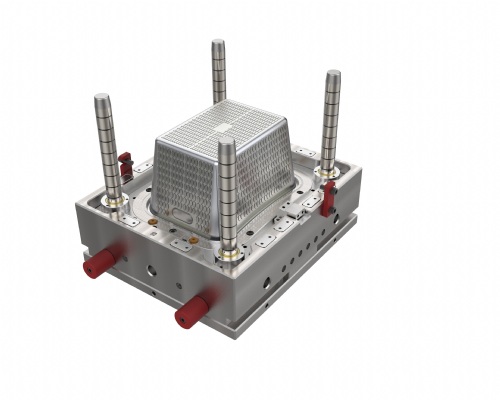

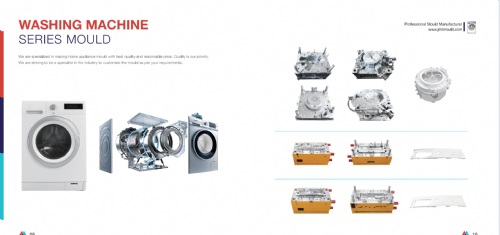

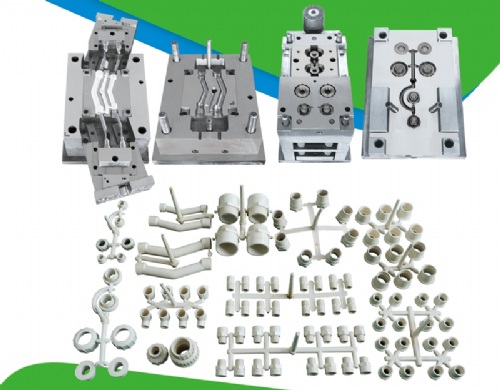

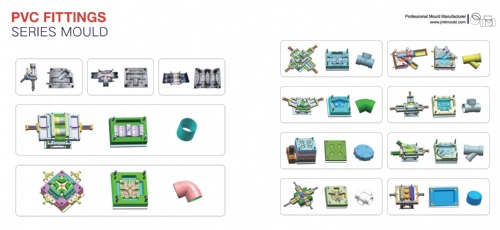

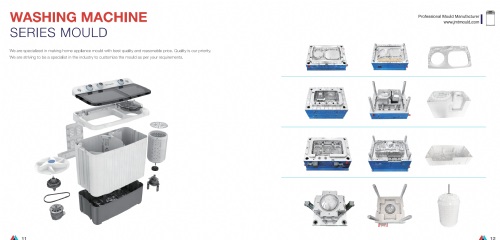

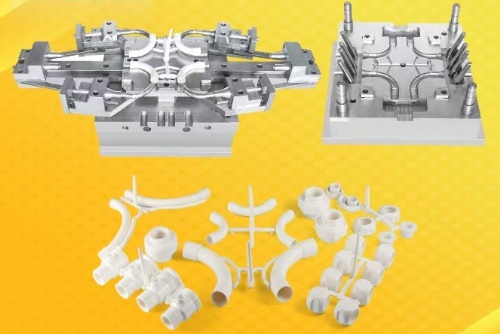

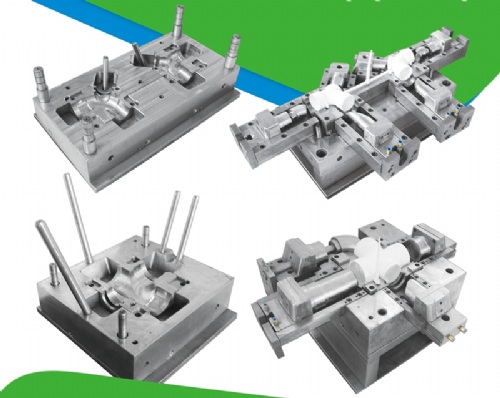

AMAN’s injection molds are engineered for high precision, long service life, and stable mass production. Each mold is manufactured using premium-grade steel such as S136 or H13, treated for high hardness, corrosion resistance and excellent polishing performance. Advanced CNC machining, EDM, and high-speed milling ensure tight tolerances and consistent product accuracy. The mold structure is optimized for smooth material flow, fast cooling, and efficient cycle times. Durable hot runner or cold runner systems can be configured according to product requirements. All mold components—core, cavity, sliders, lifters, ejector systems—are precisely fitted to guarantee stable operation and minimal maintenance. Our molds are widely used in packaging, household, medical, cosmetics and industrial parts, delivering superior surface finish, dimensional stability and long-term reliability.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry