Login

Contact

Description

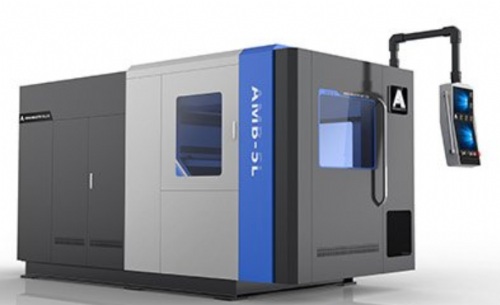

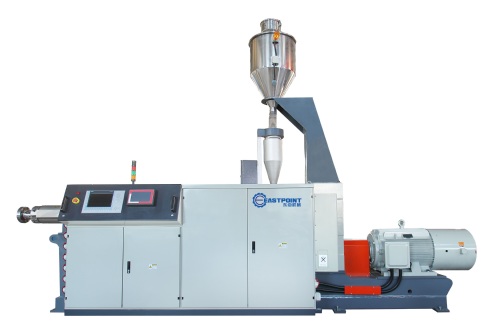

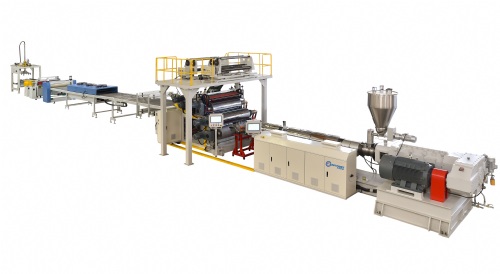

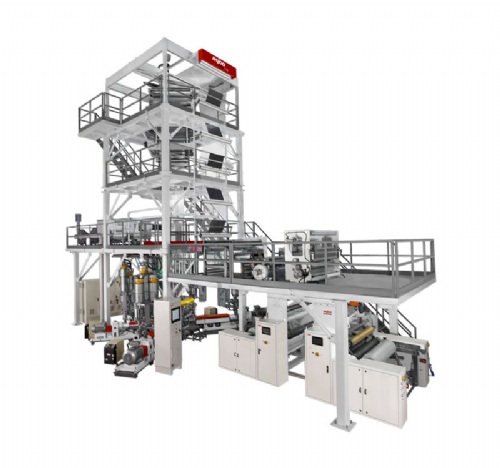

Injection Blow Molding Machine

The Aman injection blow molding machine first injects molten plastic into the mold to form a hollow preform, then transfers it to the blow mold and blows it into a high-quality, high-precision small hollow plastic bottle through air pressure.

The injection and blow molding processes are completed in one step in one machine, without intermediate transfer or secondary processing, reducing the risk of error and deformation, improving the accuracy and consistency of the bottle, while shortening production time, saving floor space, and improving your production efficiency.

According to the different clamping force, screw specifications, and sizes, the Aman injection blow molding machine provides multiple models, including AM30, AM45, AM60, AM80, and AM120, etc., to meet your production needs.

The Aman injection blow molding machine first injects molten plastic into the mold to form a hollow preform, then transfers it to the blow mold and blows it into a high-quality, high-precision small hollow plastic bottle through air pressure.

The injection and blow molding processes are completed in one step in one machine, without intermediate transfer or secondary processing, reducing the risk of error and deformation, improving the accuracy and consistency of the bottle, while shortening production time, saving floor space, and improving your production efficiency.

According to the different clamping force, screw specifications, and sizes, the Aman injection blow molding machine provides multiple models, including AM30, AM45, AM60, AM80, and AM120, etc., to meet your production needs.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry