Login

Contact

Description

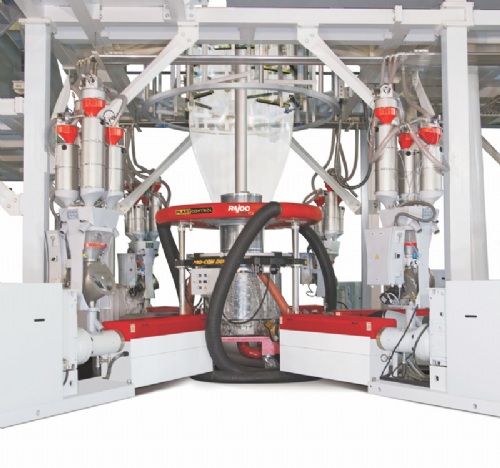

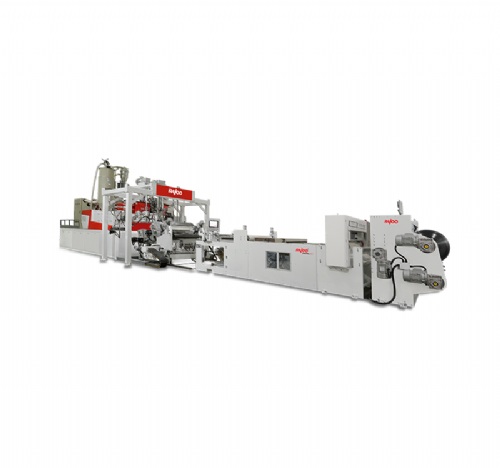

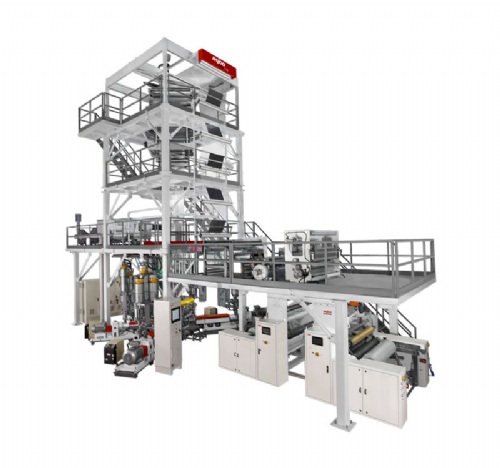

PE wax, also known as polyethylene wax, is a kind of ultra-low molecular weight polyethylene oligomer produced by the polymerization of ethylene or the cracking of polyethylene. As a key additive in plastic processing, it effectively reduces intermolecular friction (internal lubrication) and adhesion between the melt and equipment (external lubrication) in the melt through its unique polar or non-polar molecular

chain structure. This signi?cantly increases the melt index, improves the dispersion of ?llers, prevents die build-up, and reduces energy consumption. At the same time, it enhances the scratch resistance and gloss of the product surface, and is widely used in the extrusion, calendering and injection molding processes of PVC, PP, PE and other systems.

chain structure. This signi?cantly increases the melt index, improves the dispersion of ?llers, prevents die build-up, and reduces energy consumption. At the same time, it enhances the scratch resistance and gloss of the product surface, and is widely used in the extrusion, calendering and injection molding processes of PVC, PP, PE and other systems.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry