Login

Contact

Description

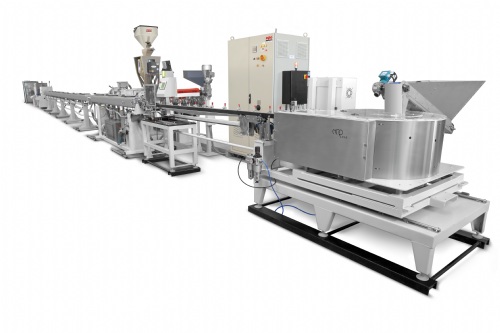

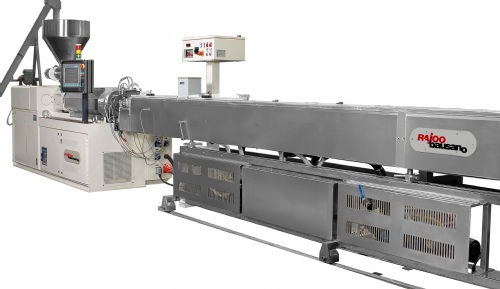

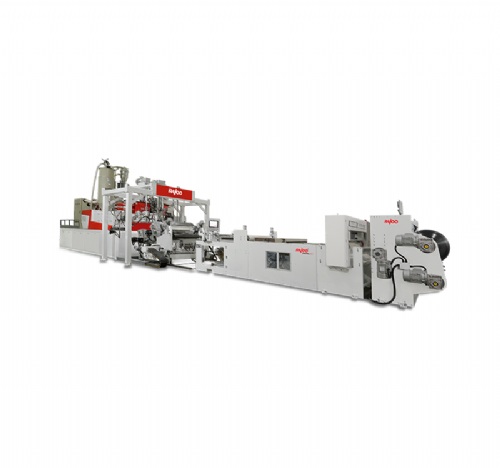

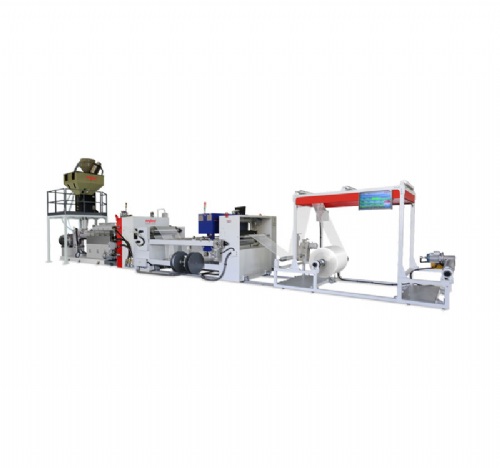

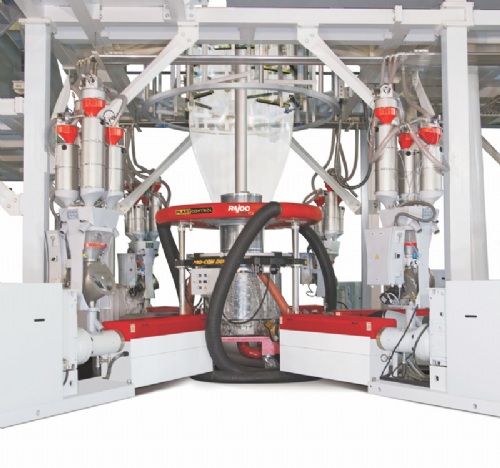

Rajoo Bausano's POLYWOOD technology leverages up to 80% wood powder to manufacture WPC profiles, including PVC/WPC flooring and WPC boards, doors, and frames. The company provides a comprehensive range of extrusion lines with outputs ranging from 200 kg/hr to 1200 kg/hr.

The Wood Plastic Composite Line includes a twin-screw extruder with a MULTIDRIVE system, a coat hanger-type die/profile die, calibrators, a calibrating table with a mold temperature controller, an embossing unit, a multi-roller take-off unit, edge trimming unit, cutting, and stacking unit.

The screw geometry in Bausano's extruders offers a wide processing window with a 36:1 L/D ratio, ensuring effective homogenization of natural fiber flour with polymers and optimal heat transmission. The extruders are equipped with a multi-vent system for moisture and volatile removal to enhance product quality.

The Wood Plastic Composite Line includes a twin-screw extruder with a MULTIDRIVE system, a coat hanger-type die/profile die, calibrators, a calibrating table with a mold temperature controller, an embossing unit, a multi-roller take-off unit, edge trimming unit, cutting, and stacking unit.

The screw geometry in Bausano's extruders offers a wide processing window with a 36:1 L/D ratio, ensuring effective homogenization of natural fiber flour with polymers and optimal heat transmission. The extruders are equipped with a multi-vent system for moisture and volatile removal to enhance product quality.

Highest Rated Products

Back

Product Inquiry

Product Inquiry