Login

Contact

Description

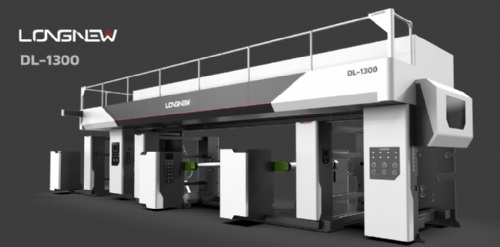

Flexographic printing has the following advantages:

Strong adaptability: Flexographic printing can adapt to various printing materials, including rough surface paper, plastic film, metal foil, etc., and is suitable for the production of large quantities of printed products.

High printing quality: Flexographic printing uses high-quality resin plates and ceramic mesh rollers, with high printing accuracy, full ink layer, and bright colors, suitable for packaging printing needs.

Good environmental performance: Flexographic printing uses low viscosity water-based ink, with fast drying speed, no pollution, and meets environmental requirements.

High production efficiency: Flexographic printing equipment has a simple structure and easy operation, suitable for high-speed multi-color printing, which can greatly shorten the printing cycle and reduce costs.

Low equipment cost: Flexographic printing machines require less investment

Strong adaptability: Flexographic printing can adapt to various printing materials, including rough surface paper, plastic film, metal foil, etc., and is suitable for the production of large quantities of printed products.

High printing quality: Flexographic printing uses high-quality resin plates and ceramic mesh rollers, with high printing accuracy, full ink layer, and bright colors, suitable for packaging printing needs.

Good environmental performance: Flexographic printing uses low viscosity water-based ink, with fast drying speed, no pollution, and meets environmental requirements.

High production efficiency: Flexographic printing equipment has a simple structure and easy operation, suitable for high-speed multi-color printing, which can greatly shorten the printing cycle and reduce costs.

Low equipment cost: Flexographic printing machines require less investment

Highest Rated Products

Back

Product Inquiry

Product Inquiry