Login

Contact

Description

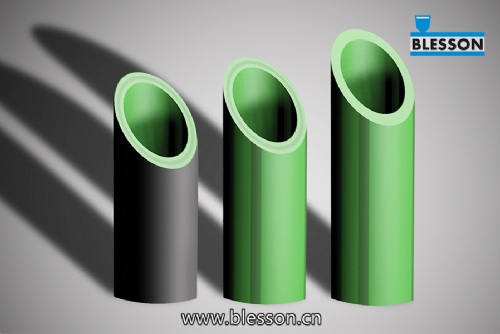

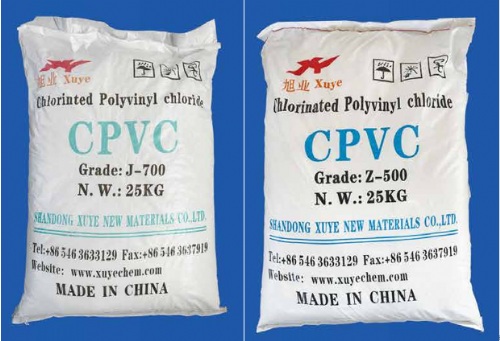

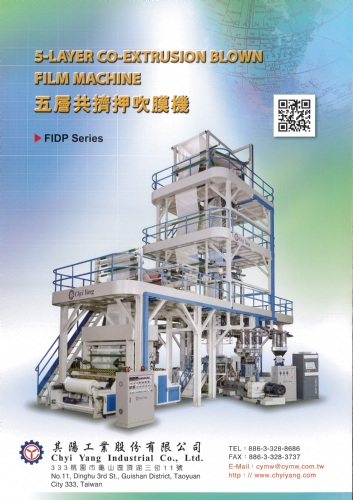

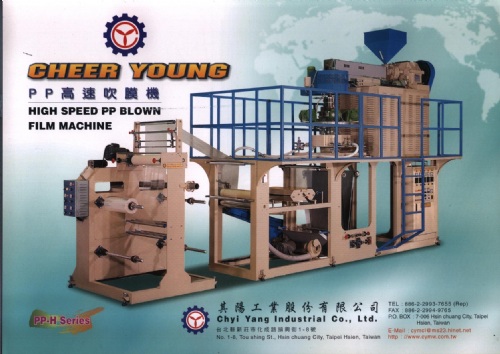

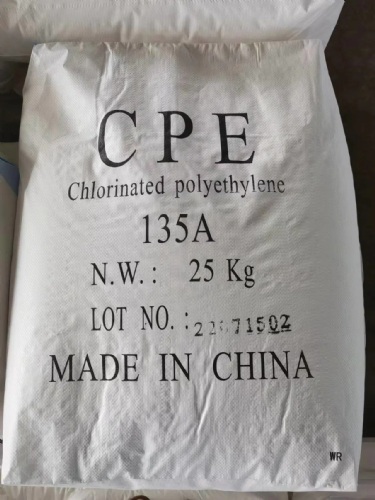

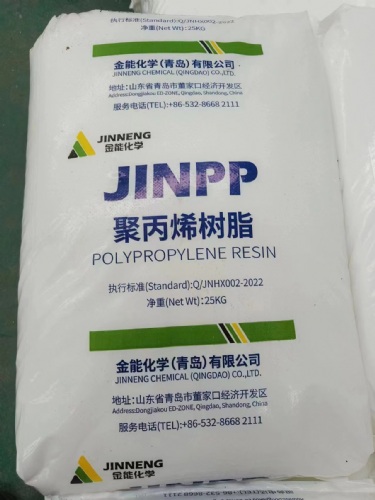

A Wood-Plastic Composite (WPC) Board Production Line is a specialized equipment setup used for manufacturing wood-plastic composite boards. These boards combine wood fibers or other plant fibers with plastics, offering the benefits of both materials. Below are the key features and applications of a WPC board production line:

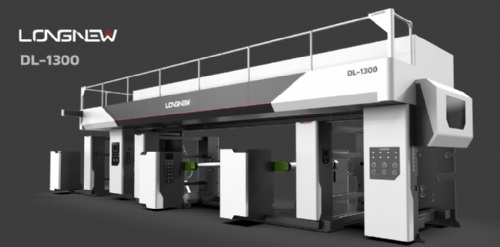

High Efficiency: Capable of continuous and efficient production of WPC boards, ensuring high productivity.

High Automation: Equipped with advanced automation control systems for easy operation and reduced labor costs.

Versatility: Able to produce WPC boards of various specifications and for different applications, meeting market demands.

Eco-Friendly: Utilizes environmentally friendly materials with low energy consumption during production, minimizing environmental impact.

Durability: Produces WPC boards that are waterproof, anti-corrosive, and weather-resistant, ensuring a long service life.

High Efficiency: Capable of continuous and efficient production of WPC boards, ensuring high productivity.

High Automation: Equipped with advanced automation control systems for easy operation and reduced labor costs.

Versatility: Able to produce WPC boards of various specifications and for different applications, meeting market demands.

Eco-Friendly: Utilizes environmentally friendly materials with low energy consumption during production, minimizing environmental impact.

Durability: Produces WPC boards that are waterproof, anti-corrosive, and weather-resistant, ensuring a long service life.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry